One of my intentions for this blog is to document techniques that I learn don’t work as well as those that do. Here’s one of my ideas that didn’t go as planned.

I decided to use a pair of M2.5 stainless screws for the end bolts of the bell push (I bought them with slotted cheese heads, then re-shaped them a little and polished them in the lathe). M2.5 was the closest modern metric equivalent to the size of the end bolts on my antique Lachenal.

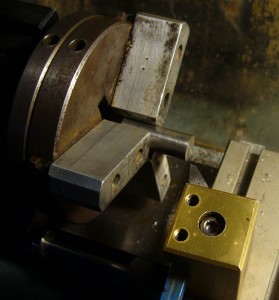

This meant I needed to make a pair of little metal captive nut plates to screw to the wooden back box with an M2.5 threaded hole in each one. Unfortunately I don’t have any M2.5 taps (M2 and M3 but not M2.5) to thread the hole with, so I thought I would instead try silver-soldering commercially made square stainless steel nuts onto thin brass plates.

Bad idea. The solder wicked into the threads of the nuts, pulled them out of position due to capillary action, and generally made a bit of a mess. I could probably clean the solder out of the nuts – if I had an M2.5 tap. But if I have to buy a tap anyway then I might as well buy a full set of them and then I can just make one-piece nut plates from thicker brass and not have to mess about with soldering and cleaning the flux and oxide off afterwards.