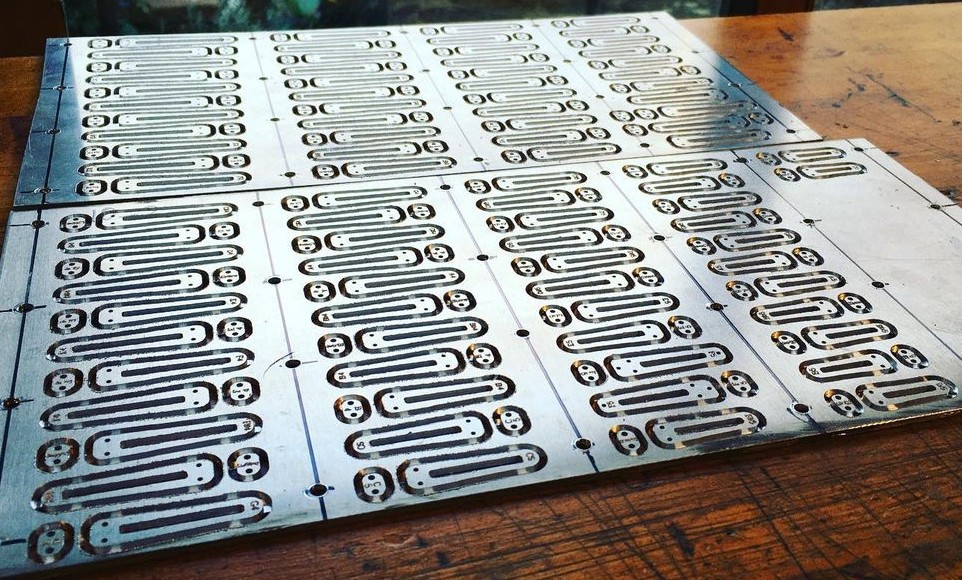

I make my own high-quality reed assemblies in the style of the best traditional English concertina makers. I use a CNC milling machine to cut out the frames from 2mm thick sheet metal, then I do many hours of painstaking manual grinding and hand filing to refine the vent slots, fit the frames to the reed pans, fit the steel reed tongues to the frames, and profile the tongues. I use my own custom reed scale, approximately equivalent to high-end vintage “long scale” instruments (apart from the left hand of most of my duet instruments, where I usually use a slightly shorter scale for balance and space reasons). Some of my instruments have brass reed frames and some have aluminium alloy. I tend to recommend aluminium to most of my clients because it is significantly lighter weight and in my opinion makes very little difference to the sound. The tongues are clamped to the frames with a pair of stainless steel screws, which is a more maintainable method than riveting them together.

A couple of plates of rough-machined aluminium reed frames before I have done any manual work on them:

I spend a lot of time using a microscope to clearly see the tight tolerances involved in reed fitting. A high definition video microscope helps to reduce eye strain compared to staring through a binocular optical scope for hours on end:

Using a modified hand file to cut the vent relief angle below the surface of the reed frame:

A set of reed assemblies after initially fitting the tongues to the frames, before profiling:

I profile the tongues with the aid of a small electric power file for removing the bulk of the metal, followed by a hand file to get it close enough to install in the frame before the first tuning stage.

A completed long scale C3 reed assembly in a brass frame. Because it is long scale, the tip doesn’t need to be heavily weighted, which allows it to start sounding faster than it would if it was shorter.

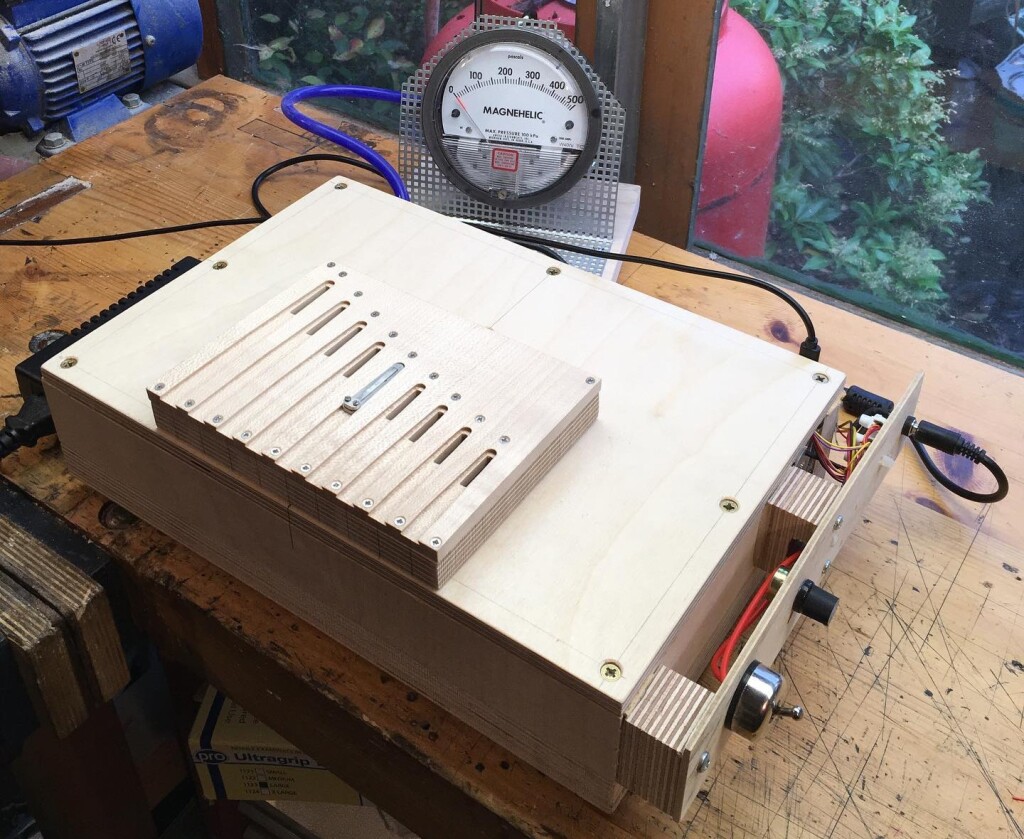

My electric reed tuning bench. I’m planning some improvements to this soon: